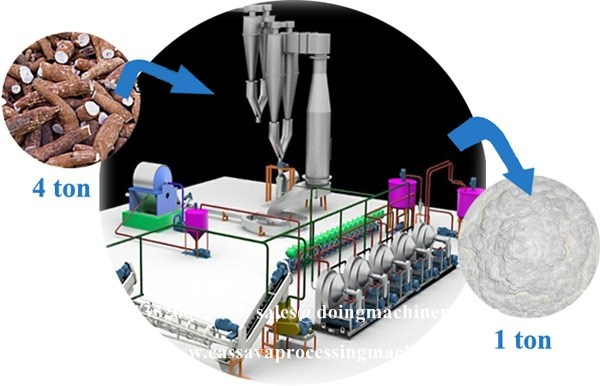

Nigeria cassava starch production business

There is high demand for cassava starch in Nigeria. It is widely used in industries such as: textile, pharmaceuticals, oil drilling, paper and packaging, gum and adhesives, chemical and household products manufacturing, battery, drinks and beverages, foods and so on. The desire to conserve foreign exchange and reduce import dependency is the driving force for demand for cassava starch especially as regards its partial substitution for corn starch in user industries. The demand for cassava starch in Nigeria is in excess of 350,000 tons per annum. The current domestic production capacity to meet the estimated demand for cassava starch is less than 20 per cent. The current price/tonne of cassava starch ranges between N150, 000 – N180, 000

Cassava starch production process introduction from Doing Company:

1.Cassava cleaning and delivery:

After weighting, cassava storage in the special area, then delivery by the conveyor to cleaning section. The storage area could put cassavas quantity can meet one hour production requests at less.

2.Desanding and cleaning process during cassava starch production line:

First use dry sieve to remove sand and other impurities, then cleaning by our rotary drum washer to completely remove the dirt in cassava surface. Use two cleaning grade,water can recycling use.

3.Cassava crushing to get starch slurry:

Doing Company newest rasper equipped with advanced technology, the crushing performance decided the starch extraction rate of cassava starch production process, our rasper can make the starch extraction rate to be more than 94%. Made the cassava starch production line highest ecnomic benefit.

Chat Online for the cassava starch machine

4.Separation:

After grit removal, the starch slurry also contain the fibres,fat and proteins, this process in cassava starch factory is used to remove the fibres from starch slurry.

5.Purification process:

Adopt 13 grade hydrocyclone system, make sure the fat and proteins removed completely from starch slurry,this guarantee the starch products quality of this cassava starch production line, ensure the starch meet all standards, after this process, we can get pure starch slurry.

6.Starch slurry dewater:

After purification process, starch slurry still high water content, can’t send to the final air drying,so need this dewater process, after this, make the starch water content less than 40%. As your different requests, we suggest you suitable dewater machine, usually choose the vacuum filter for the dewater process during cassava starch production process.

7.Starch air drying by our starch dryer:

Air drying for starch is the best method, keep starch color white, and quickly drying,make sure starch water content reach to 12%-14%, meet the first class standards.

Among is the cassava starch production process introduction. Doing Company offer this answer, and we can install the cassava starch factory for you.

Contact us freely from phone/ whatsapp: +86 135 2661 5783 / sales@doingmachinery.com

Click Cassava Processing Factory to learn more related.

Related: